C+ Torch Platform

The Arzell C+ Torch: Redefining Plasma Performance

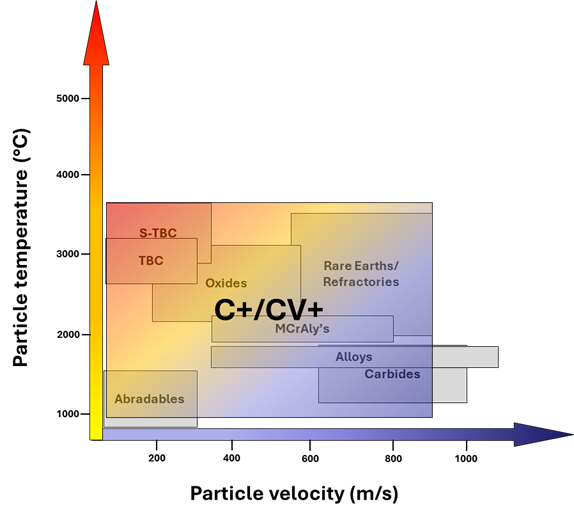

As applications become more demanding, traditional thermal spray processes have reached their limits. Coating requirements now stretch across an energy regime that demands a more effective balance of particle velocities and temperatures thus exceeding the capabilities of traditional thermal spray process types. Now, as regulations tighten and performance expectations rise, the industry needs new solutions that go beyond legacy torch designs.

The Challenge with Legacy Cascade Torches

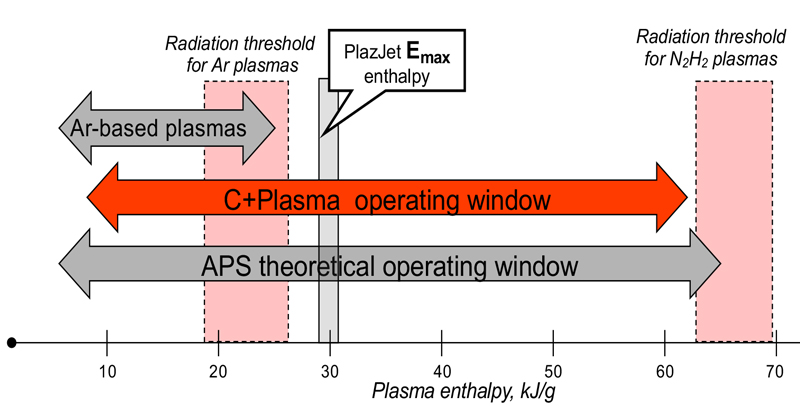

Cascade-style plasma torches improved process stability by constraining the arc, reducing the effect of fluctuations from power supply dynamics. However, this also created new challenges by increasing the heat load into the anode which limit the ability to run in high enthalpy plasma regimes. Plasma enthalpy is critical to achieving the efficiency and quality requirements of today’s coating types.

The Arzell C+ Advantage

The Arzell C+ Torch was engineered to overcome these limitations. Designed for both high-power and high-pressure applications, it delivers the broadest performance range of any plasma torch. Built with a robust, patented design, the C+ provides unmatched scalability and reliability for production environments.

Unrivaled Modularity

The defining feature of the Arzell C+ Torch allows for the torch to be scaled to operate in high enthalpy regimes as well as high pressure regimes. Its infinite control of the plasma swirl dynamics ensures that across these operating regimes, the heat flux into the anode is controlled and consistent. By switching out only the nozzle section, the gun can switch from traditional plasma operating conditions to HV type conditions, from external to internal to axial injection. Additionally, various angled and extension nozzles can be installed that allow for the torch to coat ID components as small as 2.5inches (63mm) – at power levels up to 100kW.

Key Innovations and Benefits

Wider Operating Range

The unique and robust design of the C+ has been validated in production environments for over 15 years. Initially deployed for applying TBC coatings at efficiencies exceeding 80%, the design was further refined to increase its ability to operate in high pressure regimes – usually fatal for a plasma torch. Tungsten & Chromium Carbide coatings, usually only applicable by HVOF torches are capable of being applied at less than 1/3 of the cost and without the need for any Hydrogen or other combustible gases.

The design allows for linear, intuitive particle velocity and temperature control. Operators can fine-tune parameters across the entire coating spectrum to achieve optimal results for all known coating materials.

Rethinking Performance Metrics

Power alone doesn’t define coating performance. True efficiency comes from how effectively that power is used. The C+ Torch is the only cascade torch able to use 100% molecular gas compositions, thereby exploiting the radiation limits inherent in the plasma process. N₂ based plasma radiates less than Argon based plasma – this translates directly to greater thermal efficiency, heat transfer and higher plasma enthalpy as well as a much more finite control of the plasma thermodynamics.

A Future-Ready Solution

The Arzell C+ Torch represents a major step forward in thermal spray technology. Its stability, versatility, efficiency, and expanded gas compatibility make it ideal for both R&D and production environments. As the industry pushes for increased efficiency, greater safety and better reliability, the C+ is proving to be the next-generation solution that keeps production ahead of the curve.