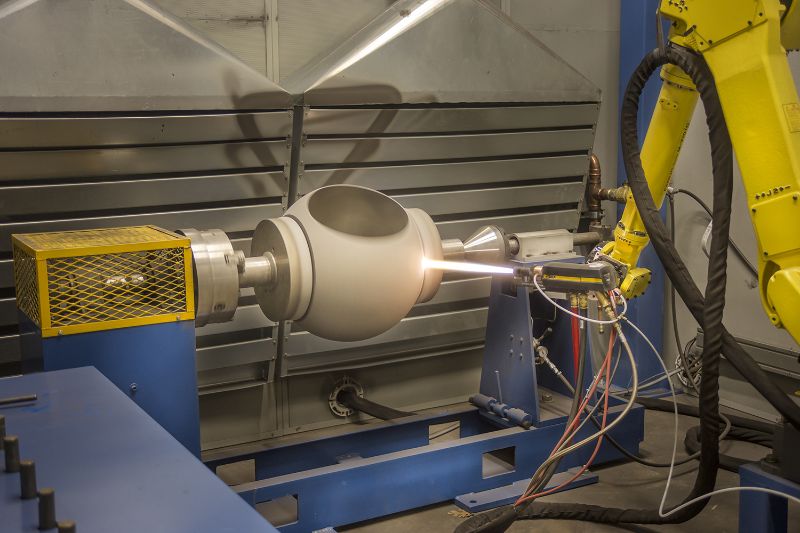

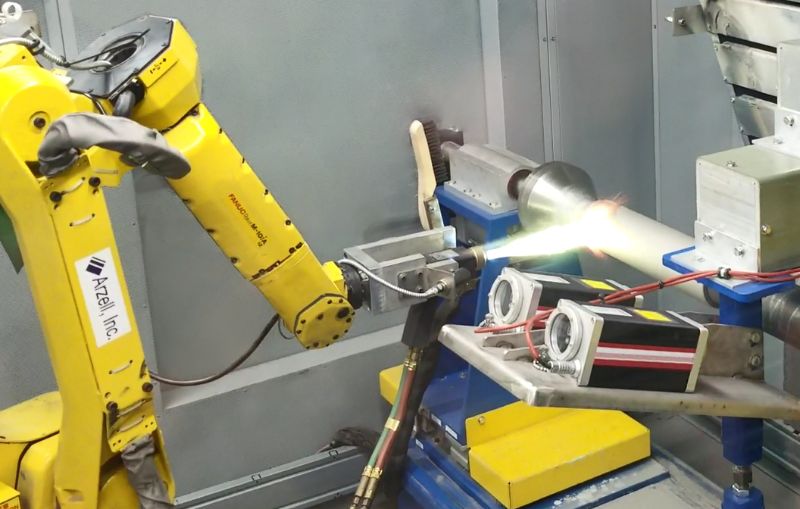

HVOF – High-Velocity Oxygen Fuel

High-velocity oxygen fuel (HVOF) is a process in which fuel and oxygen are combusted simultaneously. The fuels involved can include kerosene, hydrogen, propane, methane, natural gas, and more. The spray stream then coats a surface resulting in low porosity and high bond strength.

- HVOF Equipment Arzell, Inc. has integrated

JP, JP-5, JP-8, JP5000, JP5120, JP8000, JP8200, DiamondJet, JetKote II, JetKote III, WokaJet, WokaStar, DJ2600, DJ2700, eGun, Nova-A, NOVA-D, MP-50, HV-50, DJC, DJCE, DJFW

HVAF – High-Velocity Air Fuel

High-velocity air fuel (HVAF) is a cooler process than HVOF, allowing it to be used on a wider range of materials. The lower oxygen involved in the combustion creates coatings with higher levels of flexibility while still maintaining high hardness levels.

- HVAF Equipment Arzell, Inc. has integrated

M2, M3, C6, AK7, AK6, AK5

Arc Spray – Twin Wire Arc Spray

The arc spray process involves energizing two conductive wires to create molten materials. This material is directed through a nozzle to direct and propel the desired material. This process provides a powerful mechanical bond and is frequently used in many applications.

- Arc Equipment Arzell, Inc. has integrated

AT-400, 8830, 8835, 9910, 9935, 9985, BP-400, AWS-400, Flexi Arc, SmartArc, ValuArc

Powder Feeder

Powder feeders are an essential tool for applying coats onto materials. Our powder feeders deliver highly controlled results and offer sophisticated settings.

- Powder Feeder Equipment Arzell, Inc. has integrated

G4, V1, AT-1200, 1264, 1264i, 1264WL, Twin 10, 9MP, 9MPDJ, 5MPE, 5MP-HP, FST-10, FST-20

General thermal spray information

- Materials Typically Sprayed

Ni, Co, Cr, W, C, Al, B, Si, Fe, Y, Zr

- Gases Used in Processes

- Oxygen

- Propylene

- Propane

- Natural gas

- Kerosene

- Nitrogen

- Argon

- Helium

- Hydrogen

- Compressed air

Items that can be sprayed

- Mud rotors

- Screws

- Rolls

- Shafts

- Rockets

- Gates / Seats

- Ball Valves

- Buckets / Blades

- Vanes

- Transition pieces / Ducts

- Combustion liners

- Bearings