Laser Systems

Laser processing has become an increasingly effective method for engineering component surfaces. The precision of amplified light allows the laser beam to be accurately shaped and directed to specific areas requiring tailored material properties.

Laser cladding is particularly advantageous when a true metallurgical bond to the substrate is required. The highly controlled energy input can be precisely tuned to minimize the Heat Affected Zone (HAZ), offering a significant advantage over traditional weld overlay processes such as PTA and submerged arc welding.

Beyond cladding, laser technology is also widely used for localized heat treatment. Specific features—such as gear teeth—can be hardened to an exact depth without altering the structural integrity of the entire component, unlike conventional furnace-based heat treatment.

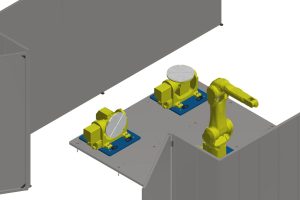

Laser systems are typically integrated with high-precision motion and handling equipment to ensure accurate synchronization between the laser and component movement. At Arzell, Inc., we engineer fully integrated laser systems capable of processing components of virtually any size or production volume.