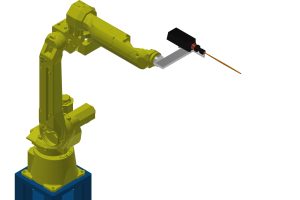

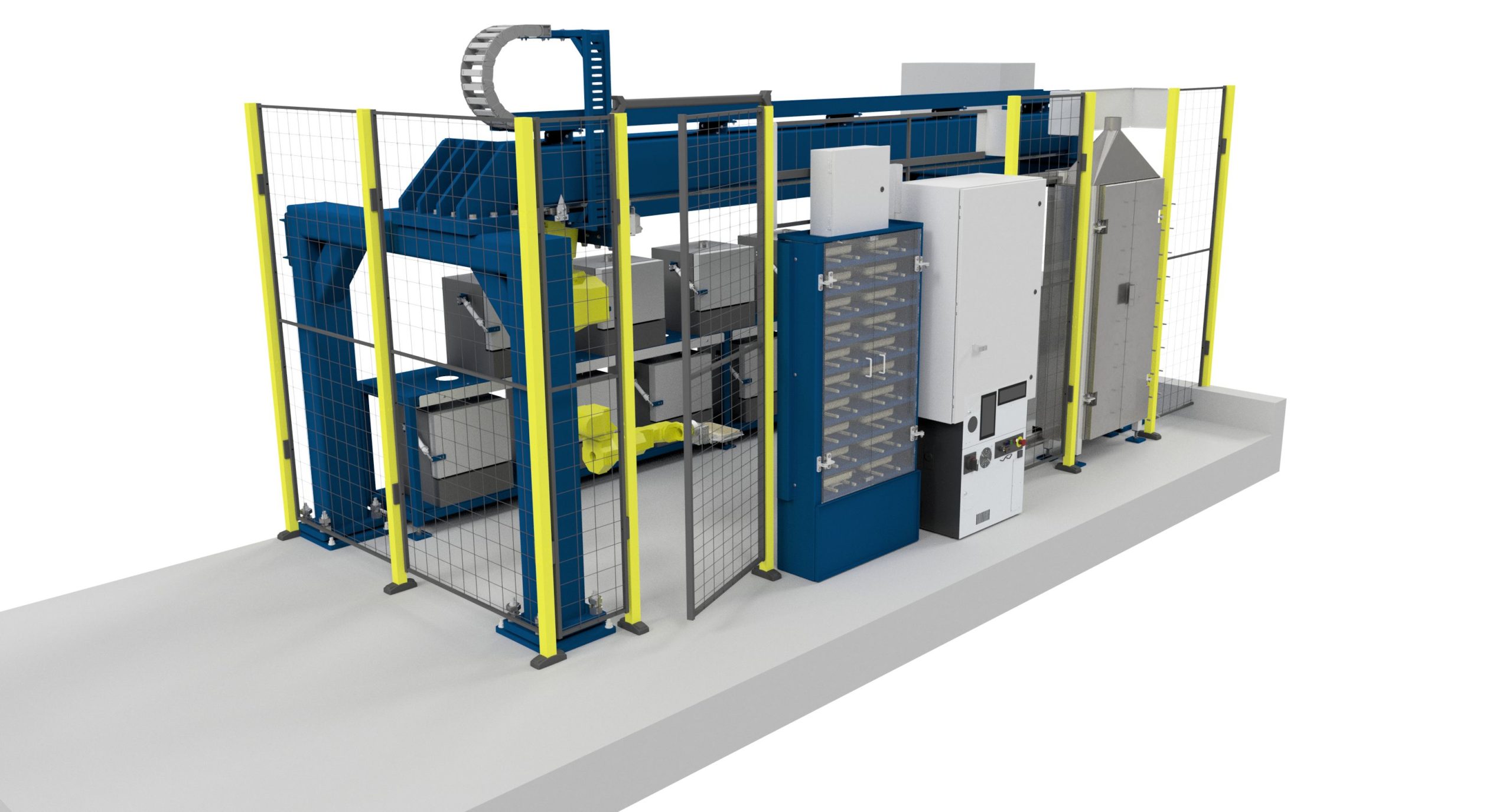

Handling Equipment:

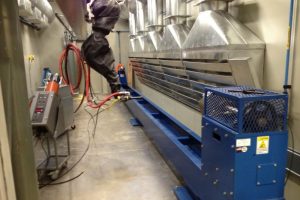

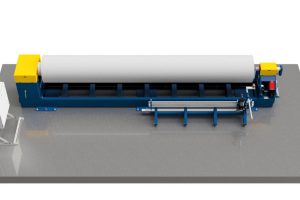

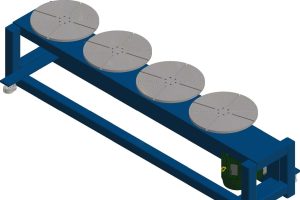

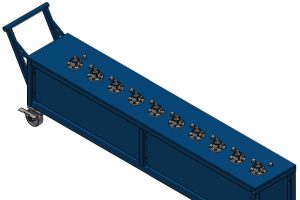

Lathes

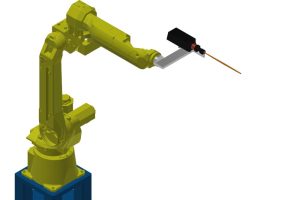

Designed for thermal spray, grit blasting, laser cladding, and many other surface treatment processes, our lathes can be configured as standalone units or fully integrated with process controllers and robotic automation. Available capabilities include:

- Multi-axis lathes

- Multi-spindle lathes

- Vertical lathes (single- and multi-spindle)

- CNC-controlled

- Thru-hole lathes for dust collection

- Air bearing or roller drive configurations

- Servo-driven systems

- Configurable lengths up to 50′

- Configurable load capacities up to 25 tons

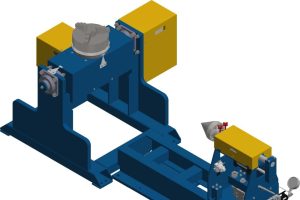

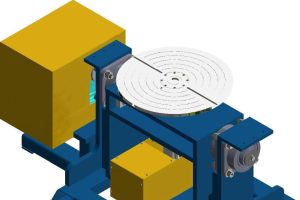

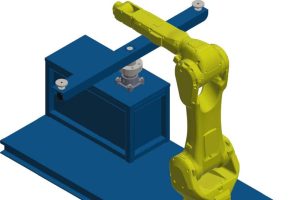

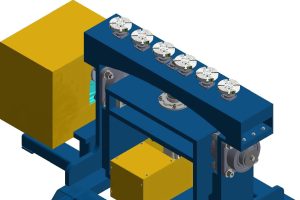

Positioners

Typically designed for more sequential and indexing applications that include welding, laser cladding, fusing as well as pick-and-place setups, our positioners can be configured as manual, standalone units or can be fully integrated as auxiliary axes with process controllers and robotic automation:

- 0-90° tilt capability

- Low & high speed options

- Servo controlled

- Rotating wall configurations

- Configurable weight limit options – up to 25 tons

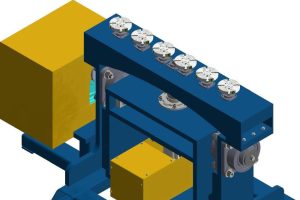

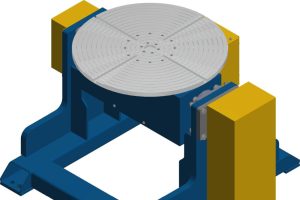

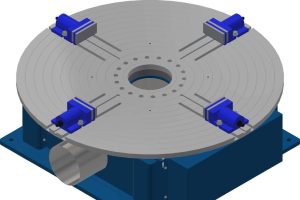

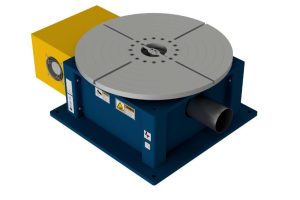

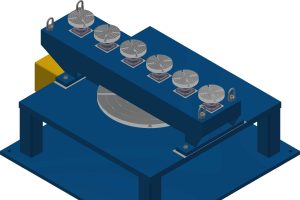

Turntables

Predominantly designed for continuous movement applications and fully configurable based on your desired application. Our wide range of turntable designs can be scaled accordingly and operated either as independent, moveable devices or completely integrated as auxiliary axes for robotic control:

- 0-90° tilt capability

- Low and high speed operability

- Air bearings

- Thru-hole/downdraft air flow

- Servo controlled

- Configured into rotating wall booth setups

- Up to 25 tons