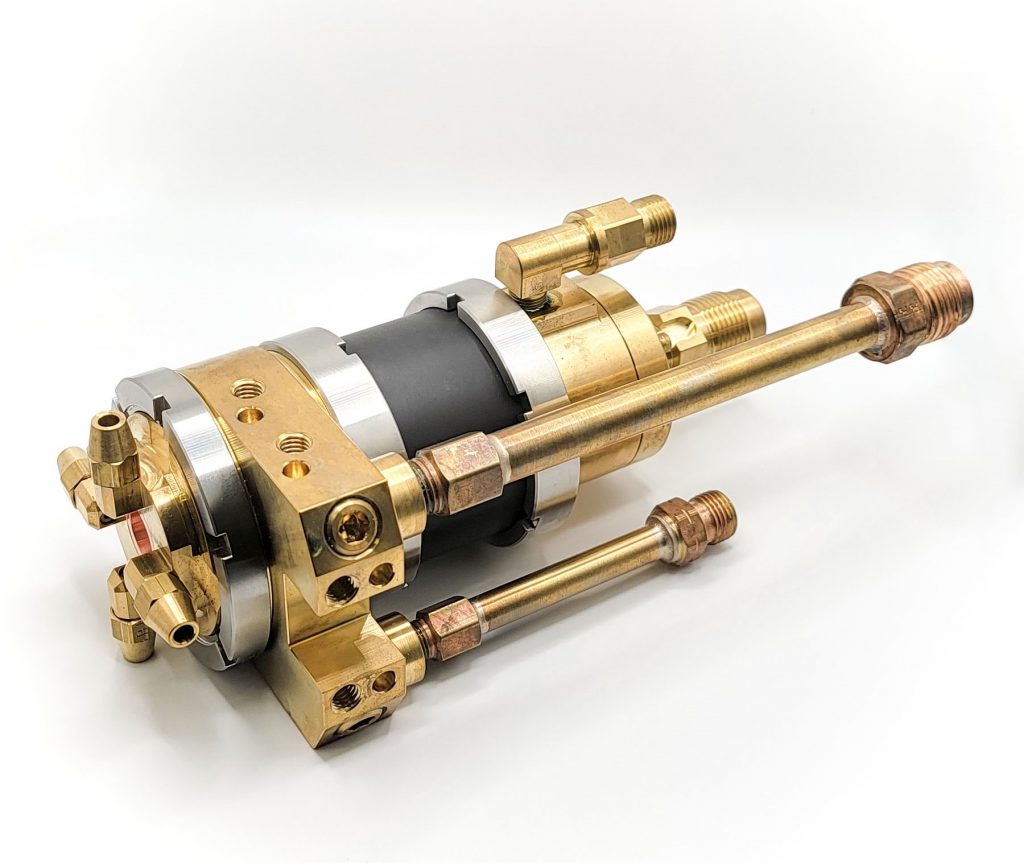

The Arzell C+ Plasma Torch

One Platform. Every Coating.

The future of thermal spray demands more—more efficiency, more flexibility, more control. The Arzell C+ Plasma Torch delivers all three.

What Sets the C+ Apart

- High-Enthalpy Plasma – Up to 60 kJ/g at modest power levels

- Modular Performance – Switch between plasma and high-velocity modes by changing the nozzle

- Unmatched Versatility – Spray ceramics, metals, and carbides with one system

- ID Coating Capability – Down to 2.5 inches

- Safer Operation – Apply carbide coatings without hydrogen or combustible gases

Better Coatings, Lower Cost

Higher plasma efficiency means:

- More material deposited per pass

- Shorter spray times

- Lower gas and power consumption

- Longer component life

Built for Production

The C+ platform has been trusted in production environments for over 15 years and integrates seamlessly into automated or manual systems.

The C+ Torch isn’t just better plasma—it’s better business.

Connection Requirements

| Electrical | 120/220VAC, 50/60Hz, 5A |

| Cathode gas Argon Nitrogen Hydrogen Helium Anode gas Argon Nitrogen |

250 scfh @ 85 psi (120 l/min @ 5.8 bar) 250 scfh @ 85 psi (120 l/min @ 5.8 bar) 50 scfh @ 100 psi (24 l/min @ 6.8 bar) 150 scfh @ 100 psi (70 l/min @ 6.8 bar)50 scfh @ 85 psi (24 l/min @ 5.8 bar) 50 scfh @ 85 psi (24 l/min @ 5.8 bar) |

| Carrier 1 – Argon Carrier 2 – Argon |

50 scfh @ 85 psi (24 l/min @ 5.8 bar) 50 scfh @ 85 psi (24 l/min @ 5.8 bar) |

| Chiller | 15 tons (55 kW), Model 3 torch 20 tons (70 kW), Model 5 torch |

| Water flow and pressure | 12 gpm @ 175psi (45 l/min @ 12 bar) |

| Power supply, 100kW | 380/480V, 3-phase |

| Operator interface | 15” touch screen |

| Powder feeder | Uniquecoat G4 preferred |

Contact us for pricing, availability and more information.