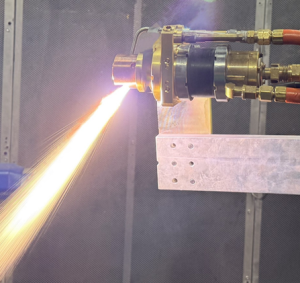

HVOF – High-Velocity Oxygen Fuel

High-velocity oxygen fuel (HVOF) is a combustion process that creates a pressurized gas stream where an optimized powder feedstock is injected into and accelerated up to supersonic velocities. Maximum process temperatures are considerably lower than the traditional plasma spray process which therefore offers distinct advantages for temperature sensitive materials and, combined with the high velocities, generates coatings that offer superior mechanical properties.

HVLF: Utilizes a liquid fuel type (kerosene, Jet A1, ethanol) combusted together with oxygen in a chambered torch design. This creates high pressure conditions that, once expanded through a laval nozzle ensures high mach gas velocities.

HVGF: Utilizes gas fuel types (hydrogen, propane, methane, natural gas) that also combust with oxygen however torch designs are somewhat different than their liquid fueled counterparts. Gas fueled torches typically do not use a traditional chambered design which allows for axial powder injection.

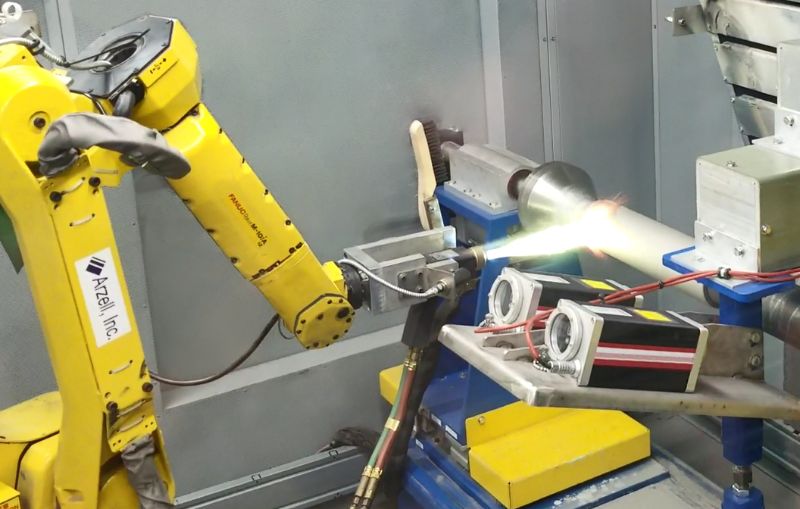

HVOF Controller and Torch Equipment Arzell, Inc. has integrated

MULTUS LF & GF, JP, JP-5, JP-8, JP5000, JP5120, JP8000, JP8200, DiamondJet, JetKote II, JetKote III, WokaJet, WokaStar, DJ2600, DJ2700, eGun, Nova-A, NOVA-D, MP-50, HV-50, DJC, DJCE, DJFW

HVAF – High-Velocity Air Fuel

High-velocity air fuel (HVAF) is a combustion process, similar to HVOF however, the process utilizes compressed air rather than oxygen as a reactant to combust the fuel. Maximum process temperatures are slightly lower than the HVOF process and the lower oxygen contents typically result in coatings with lower oxidation.

HVAF Controller and Torch Equipment Arzell, Inc. has integrated

M2, M3, C6, AK7, AK6, AK5, i5, i7, C01, Ultracoat

Arc Spray – Twin Wire Arc Spray

Arc Spray is an electrical process that utilizes wires as electrodes which are melted on contact and then atomized to create metallic droplets. The process offers the lowest operating costs and highest efficiencies but is restricted to conductive alloys as feedstock materials. We are proud to lead the industry into new territory with pulsed DC power supply technology. This is changing the game in terms of coating efficiency and quality.

Arc Equipment Arzell, Inc. has integrated

Elmatech LDS MIDI 400, MB, IB, HB, AT-400, 8830, 8835, 9910, 9935, 9985, BP-400, AWS-400, Flexi Arc, SmartArc, ValuArc

Powder Feeding

Material delivery is almost a science in and of itself. Getting the powder to the torch reliably is critical for applying repeatable and consistent coatings. This is often compounded by differing powder properties such as density, morphology and size range. Our fundamental understanding of the science helps determine the best feeder type for the application.

Powder feeder equipment Arzell, Inc. has integrated

G10, G4, V1, AT-1200, 1264, 1264i, 1264WL, Twin 10/120, 9MP, 9MPDJ, 5MPE, 5MP-HP, FST-10, FST-20

General thermal spray information

Materials typically sprayed

Various metallic and ceramic alloy combinations of Ni, Co, Cr, W, C, Al, B, Si, Fe, Y, Zr, Li, Si, La, Ti

Gases typically used

Oxygen, Propylene, Propane, Natural gas, Kerosene, Nitrogen, Argon, Helium, Hydrogen, Compressed air

Items that can be coated

Mud rotors, Screws, Rolls, Shafts, Rocket nozzles, Gates/Seats, Ball Valves, Buckets Blades, Vanes, Transition Pieces/Ducts, Combustion liners, Bearings