Robot Programming

The foundation of production efficiency and safety improvements is automation. This is accomplished most effectively with Robots and robotic integration. However, the tasks, operations and paths need to be taught. Robotics and programming are fundamental to us. Our team has an extensive background in programming and can be deployed on-site to program complex componentry or can offer off-site programming using 3D models.

Maintenance and Repair Services

Downtime of your equipment can take a serious toll on your business. Luckily, at Arzell, Inc., we offer fast and effective solutions to get things fully operational again. For both existing and new clients, we are always dedicated to providing the highest levels of service and support. At Arzell, Inc., we are proud to be more than a provider, but a complete solution for businesses in our industry. We offer both maintenance and repair services for a wide variety of parts, robotics, thermal spray equipment, and much more. Our services can also help to optimize existing machines and parts. This would include actions like adjusting, cleaning, lubricating, and much more. To find out more about our maintenance and repair services, download this brochure. Please refer to the Safety Inspections section below for specific types of equipment.

Safety Inspections

Inspections are a necessary part of managing a business. Without them standards would not have to be met, and conditions would decline. At Arzell, Inc., we are happy to provide you with a thorough safety inspection to ensure that your systems meet the proper criteria. Our inspections give companies a better idea of where they stand when it comes to future inspections and alerts them of what needs attention. We have a highly experienced safety team that stays up-to-date on all of the latest safety requirements, regardless of your industry. If you’re curious about our safety inspections, please download them below. The price of this service typically ranges from $995 to $2,650 depending on the equipment. Bundling pricing may be available to address multiple pieces of equipment in the client facility. Give us a call for specific pricing that fits your needs.

Chiller

Dust Collector

Spray Equipment Lathe 3-Axis

Spray Equipment Lathe

Spray Equipment Lathe Polisher

Spray Equipment Lathe Without Traverse

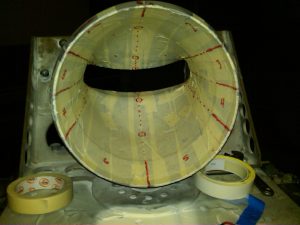

Spray Robot

StripTank

Training

When new equipment and processes are implemented, working instructions for proper maintenance and operation usually require change. When you are considering a new investment in automated technologies or thermal spray integration, or if you are simply managing personnel turnover, addressing training needs is critical to continued operational success. At Arzell, Inc., our technicians and safety experts will provide you and your employees with a detailed and hands-on training course. It will ensure that both your equipment and employees remain safe and perform at full optimal capacity.